Greek ships mooring lines can tie the world together-literally!

Greek ships except making the world go round they have mooring lines to become the foundation of future space docking technology.

Christos Leoussis examines the evolution, technology, and market of mooring lines as the backbone of global shipping and maritime innovation.

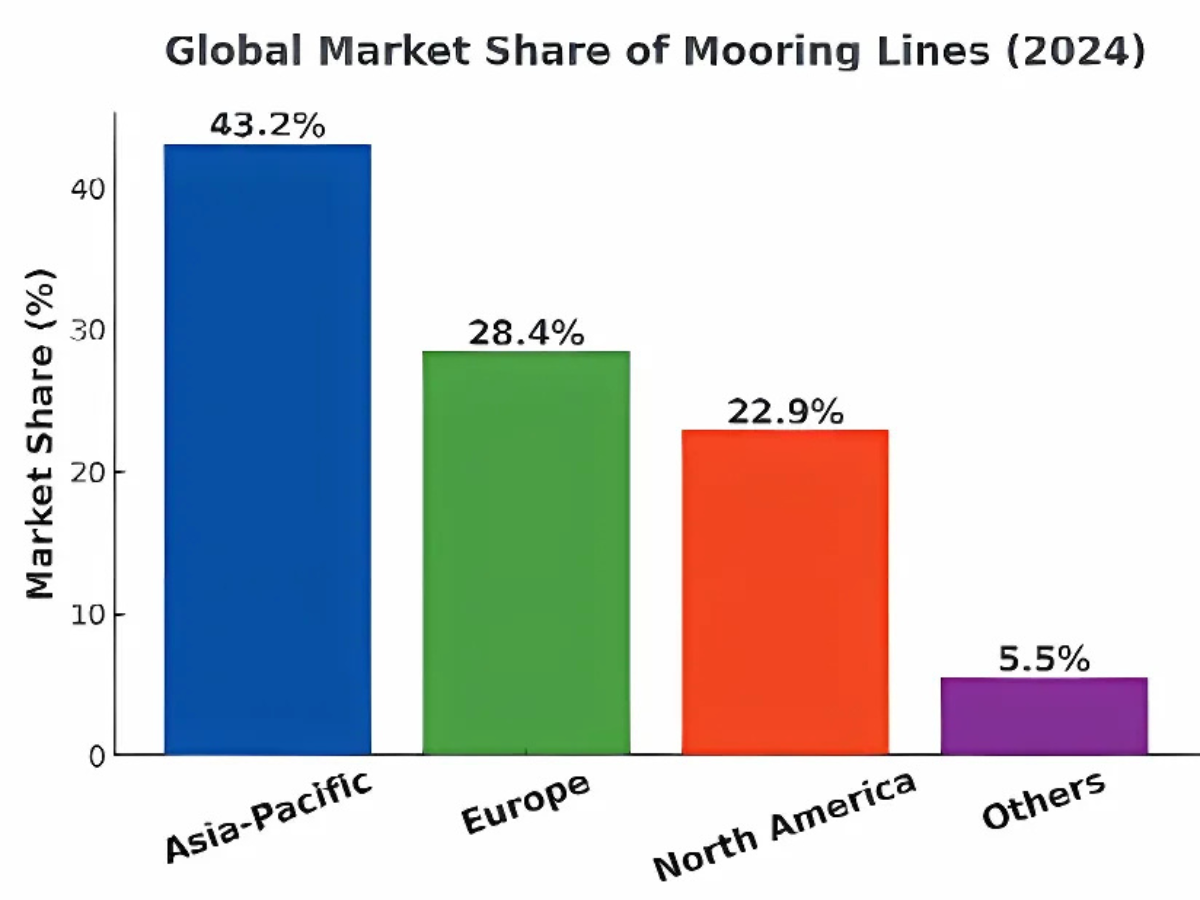

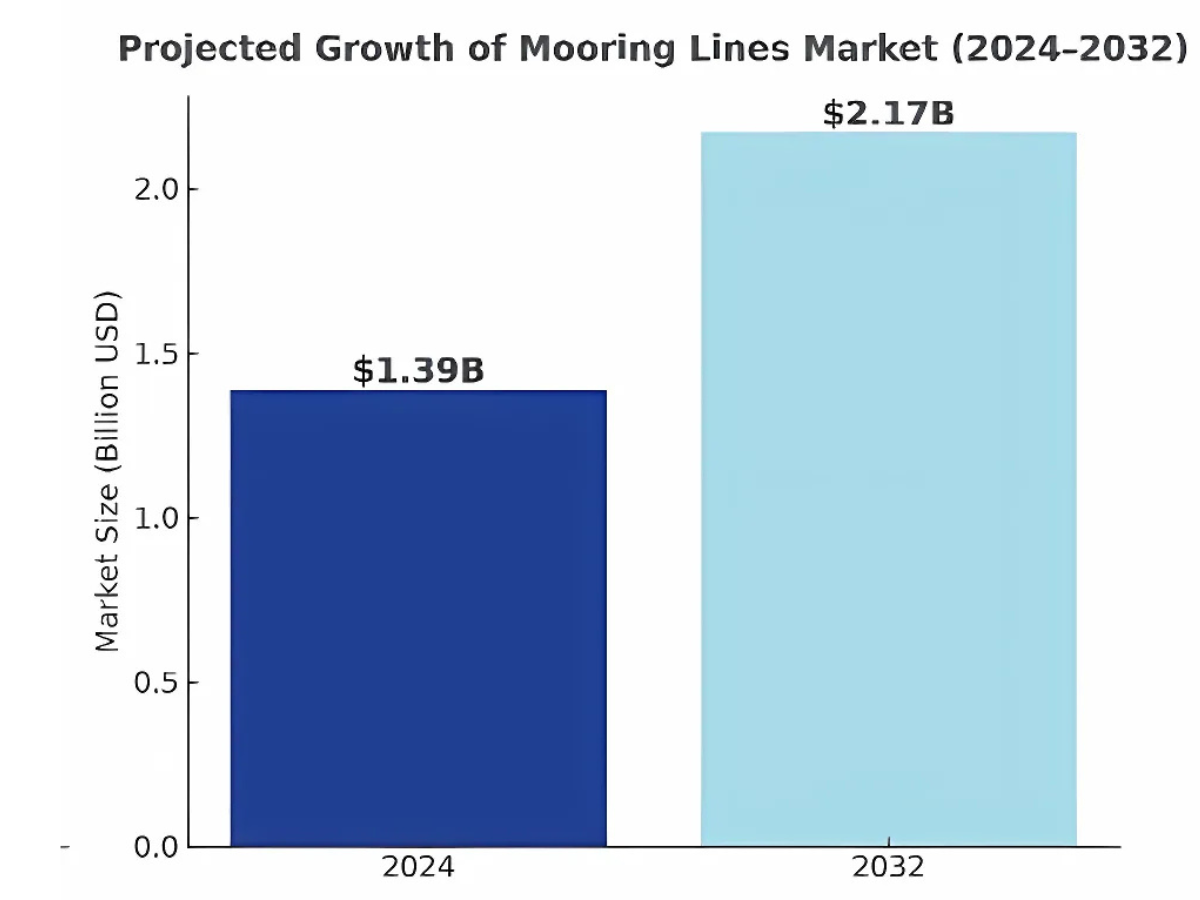

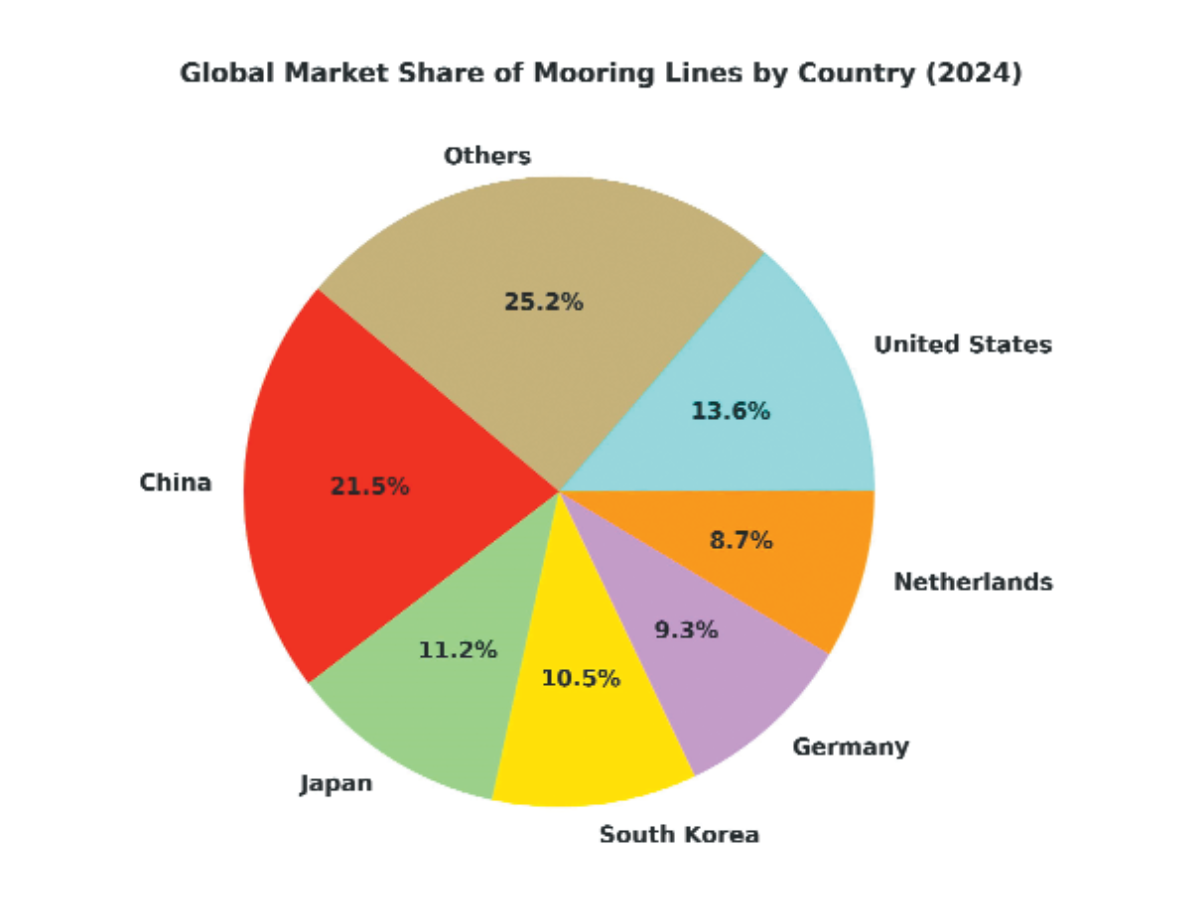

The production of mooring lines has become a specialized industry, with manufacturing hubs distributed across various regions. As of 2024, the global mooring ropes market was valued at approximately USD 1.39 billion, with projections indicating growth to USD 2.17 billion by 2032. Asia-Pacific stands as the dominant player in this sector, accounting for 43.16% of the market share in 2024. This prominence is largely attributed to countries like China, Japan, and South Korea, which have robust maritime

industries and advanced manufacturing capabilities. Europe and North America also hold significant portions of the market, with countries such as Germany, the Netherlands, and the United States being notable producers. China is a major player in this sector and its dominance stems from a combination of factors; significant investments in modern manufacturing facilities, coupled with a skilled workforce, enables them to produce ropes meeting international standards while achieving economies of scale.

Furthermore, access to raw materials and a competitive market environment have driven innovation and quality improvement. Many Chinese manufacturers now adhere to strict quality control processes and hold certifications from reputable organizations in similar fashion to their global competition.

Innovation at sea

Today, modern mooring lines are a blend of high-performance materials and cutting-edge technology. Highmodulus polyethylene (HMPE) ropes have become standard for many commercial and naval vessels. These lines are incredibly strong – pound for pound, stronger than steel – while remaining lightweight and easy to handle. Advanced coatings and treatments further enhance their resistance to abrasion, chemicals, and extreme weather conditions. Additionally, modern mooring lines often incorporate color coding and reflective threads, allowing for better visibility during night operations or poor weather conditions. Several factors contribute to enjoying a high-quality mooring rope. First and foremost is its strength and durability. It must withstand the immense forces exerted by wind, currents, and vessel weight. Material composition and total weight per piece is vital; high-quality ropes must ensure excellent strength-to-weight ratios and resistance to abrasion, UV degradation, and chemical exposure. Construction plays a role – braided or twisted – each offering unique properties. Elongation characteristics are also important, allowing the rope to absorb shocks without snapping. Finally, consistent quality control during all manufacturing stages is essential.

Another breakthrough in contemporary mooring technology is the use of load monitoring systems. Embedded sensors within the lines provide realtime data on tension and strain, enabling crews to make adjustments before a line reaches a critical breaking point. This technology reduces the risk of line failure, a serious hazard that can cause injury or damage to the vessel and dock. Furthermore, some mooring systems now utilize automated mooring units, such as vacuum pads or magnetic clamps, reducing reliance on manual line handling and boosting operational efficiency. Charter parties often specify requirements for mooring ropes, including their type, size, and condition. The responsibility for providing and maintaining these ropes can be a point of negotiation between the shipowner and the charterer.

A vessel’s ability to moor safely and efficiently is crucial for fulfilling charter obligations and avoiding delays or potential disputes. The evolution of mooring lines reflects the broader narrative of maritime innovation – a continuous quest for efficiency, safety, and durability. As ships grow larger and global trade becomes more complex, mooring

systems must adapt, incorporating automation and smart technology. Some modern ports are experimenting with vacuum mooring systems and magnetic docking methods, hinting at a future where traditional ropes may become obsolete. Yet, for now, mooring lines remain an essential link between sea and shore, embodying centuries of maritime

history in every fiber and strand.

Pricing

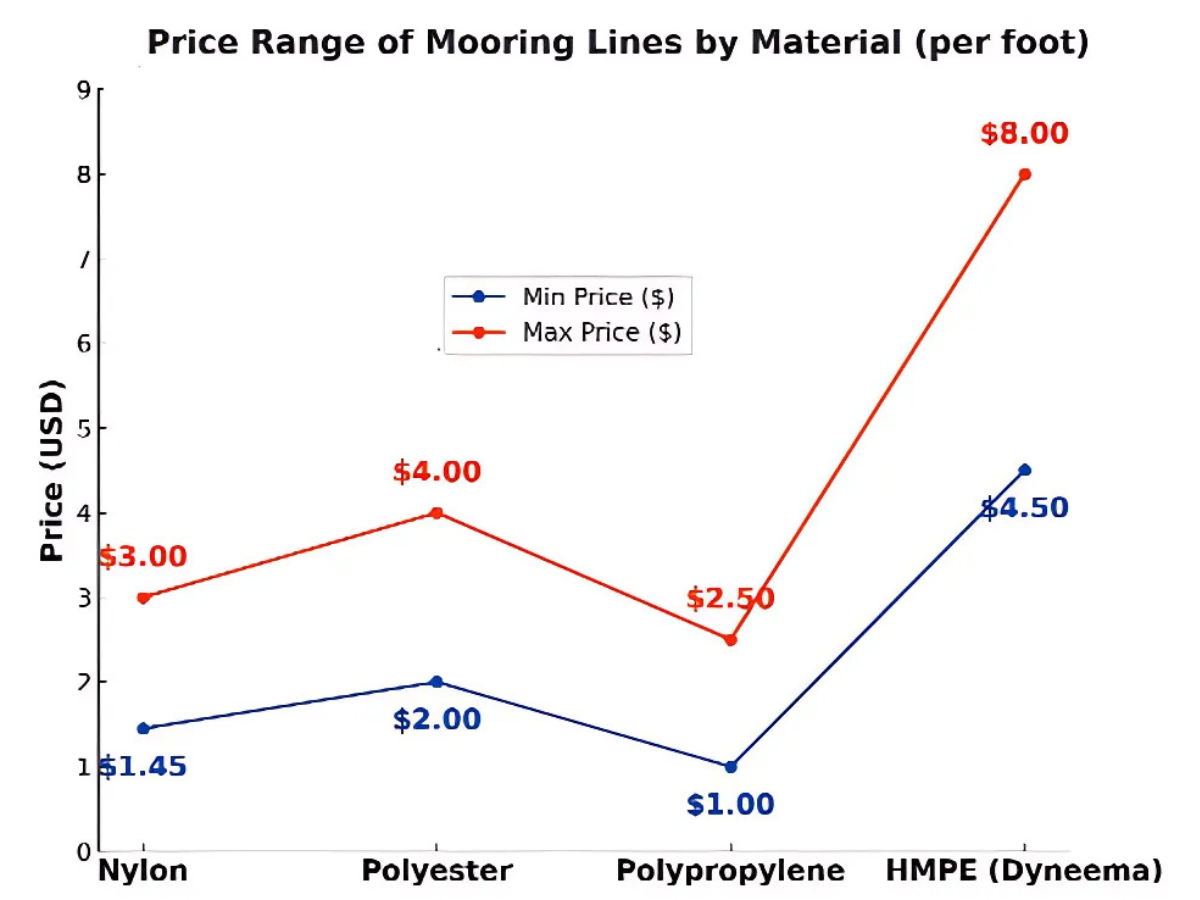

The cost of mooring lines varies based on material, diameter, construction, and brand. For instance, prices can range from $1.45 per foot (approximately $4.76 per meter)

for standard nylon lines to higher amounts for specialized ropes. High-performance lines made from materials like high-modulus polyethylene (HMPE) or those with advanced coatings tend to be priced higher due to their superior strength and durability. Additionally, customizations such as added coatings, color coding, or embedded sensors can further influence the price.

On Chinese Market:

• Mixed Ropes – Polypropylene / Polyester: 1.40-2.20 USD/kg (depending on the quality of raw material)

• Nylon Ropes: 2-3.8 USD/kg (depending on the quality of raw material)

• UHMWPE Ropes: 11-22 USD/kg (dependingon the quality of raw material)

Technological advancements

Modern mooring lines have benefited from significant technological advancements. The integration of load monitoring systems, where sensors embedded within the lines provide real-time data on tension and strain, has enhanced safety and operational efficiency. Furthermore, the development of automated mooring units, such as vacuum pads or magnetic clamps, has reduced reliance on manual line handling, streamlining docking procedures.

Lines length according to vessel type

The length of mooring lines used by modern vessels varies significantly depending on the type and size of the ship:

• Containerships: Typically use 200 to 300 meters (656 to 984 feet) of mooring line per rope. Large containerships may carry 8 to 12 mooring lines for both bow and stern, totaling around 2,400 to 3,600 meters (7,874 to 11,811 feet) of mooring rope onboard.

• Bulk carriers: Usually require 150 to 250 meters (492 to 820 feet) per line, with around 6 to 10 lines used. This adds up to 1,500 to 2,500 meters (4,921 to 8,202 feet) of rope in total.

• Tankers (VLCCs/ULCCs): Due to their massive size, they often use 250 to 350 meters (820 to 1,148 feet) per line. A large tanker might have 10 to 16 lines onboard, amounting to 3,000 to 5,600 meters (9,843 to 18,373 feet) of mooring line.

The total length depends not only on the vessel’s size but also on port requirements and safety margins.

From plant fibers to steel cables

The Industrial Revolution marked a pivotal shift in the composition and strength of mooring lines. As ironclad steamships replaced wooden sailing vessels, the demands on dock lines intensified. Natural fibers, though still in use, began to give way to wire ropes – steel cables that offered unprecedented durability and load-bearing capacity.

Shipyards and ports adopted these wire mooring lines to accommodate the sheer size and weight of modern ships. The shift was not without challenges: wire ropes, while strong, were heavier and less flexible than their fiber counterparts, requiring winches and other mechanical aids for handling.

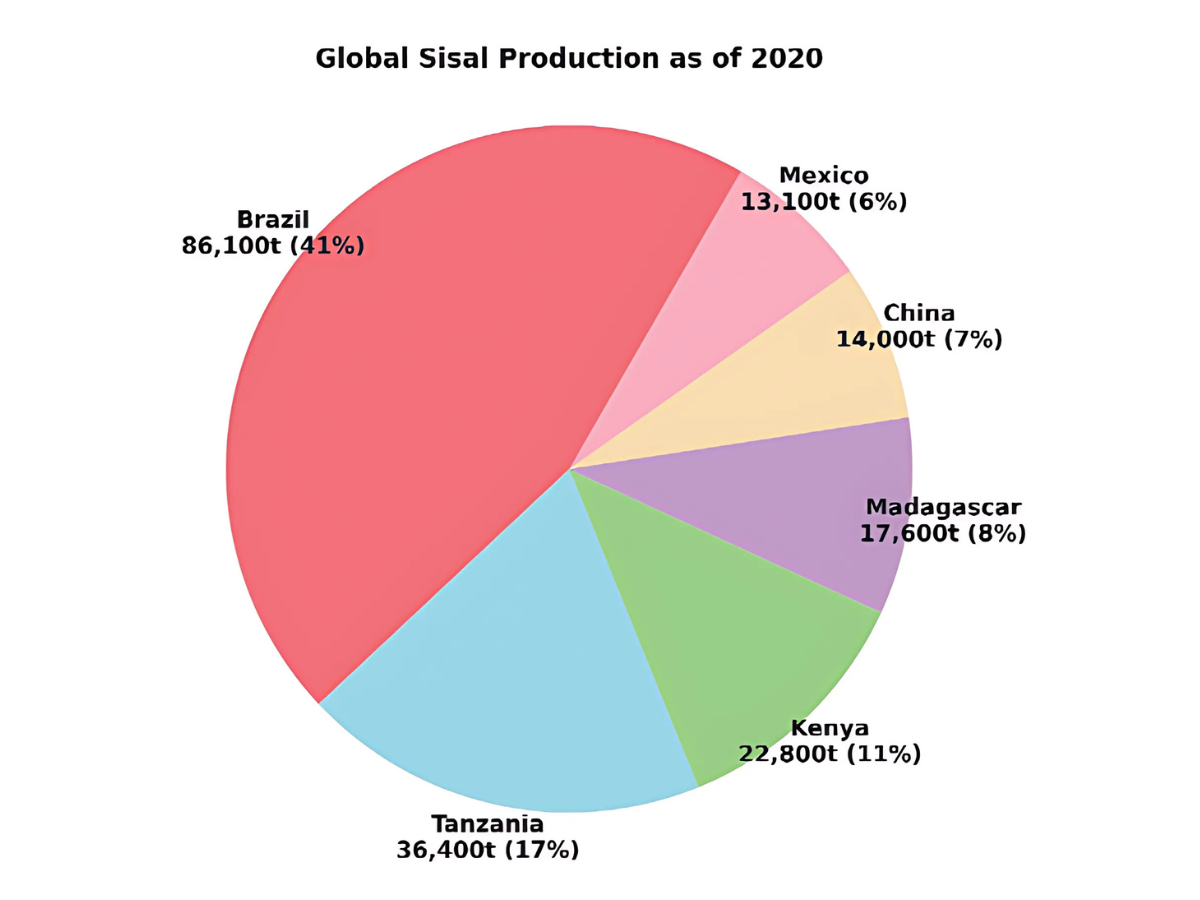

The 1950s to 1970s saw a significant rise in the use of sisal ropes, especially in maritime applications. Sisal, derived from the Agave sisalana plant, was known for its durability, saltwater resistance, and affordability. During this period, Tanzania emerged as a global leader in sisal production, contributing around 17% of the world’s supply by 2020, alongside neighboring countries like Kenya and Madagascar. The combined efforts of these East African nations accounted for roughly 36% of global sisal output. Sisal marine ropes, crafted from the fibers of the agave plant (Agave sisalana), have long played a role in maritime history.

These natural fiber ropes are known for their strength, affordability, and resistance to saltwater – qualities that made them popular for mooring lines, fishing nets, and general ship rigging before synthetic alternatives took over. The cultivation of sisal is predominantly centered in specific regions, with Tanzania and its neighboring countries playing significant roles in global production.

The Greeks and Sisal production

As of 2020, global sisal production was approximately 210,000 tonnes. The leading producers were Brazil, Tanzania, Kenya, Madagascar, China and Mexico. Collectively, Tanzania, Kenya, and Madagascar contribute about 36% of the world’s sisal production. The Greek community has had notable involvement in East Africa’s sisal industry, particularly in Kenya. During the late 1950s, Greeks were actively engaged in sisal farming. A prominent example is the Teita Sisal Estate Limited, recognized as the largest sisal estate in East Africa, owned by an investor of Greek origin. This company primarily cultivates sisal for export to countries such as Nigeria, China, Spain, and Morocco.

Some fun comparison facts of the Greek Fleet Mooring Lines !!!

Greek fleet’s total mooring line length.

The Greeks have 6,000 ships. Each ship has 5,000 meters of mooring lines. That’s: 6,000X5,000=30,000,000 meters of rope. The equator is 40,075,000 meters long. So, the combined length of all Greek ship ropes is about 75% of the Earth’s equator. In practical terms, the Greek ropes could stretch:

• From the North Pole to the Equator and a bit beyond – you’d still be 10 million meters short of a full loop.

• Or, you could cover the distance from New York to Buenos Aires – and have a bit left over for a tug-of-war match in Rio.

And now what Greek ropes could do in the solar system!!

The Greek ropes can’t make it all the way around the Earth’s equator – but they could definitely lasso a planet or two. Maybe start small… like roping in Mercury (which has an equatorial circumference of just 15 million meters). You could wrap the ropes around Mars’ equator – which is just 21 million meters – with plenty to spare! If the Greeks want to stretch their 30 million meters of rope around the solar system, here’s how they measure up:

Mercury (15 million meters): The Greeks could give Mercury a double hug – one lap around, then another, just to make sure it’s tied down properly. Maybe Mercury’s always in a rush because no one’s anchored it with mooring lines!

Venus (38 million meters): So close! They’d fall about 8 million meters short – almost like trying to zip up your jeans after a big meal. Venus remains untethered, free to spin in its weird backward rotation.

Mars (21 million meters): They could circle Mars once and still have 9 million meters left – enough to give Phobos and Deimos (Mars’ tiny moons) a nice little leash, just in case Mars decides to wander off.

Jupiter (439 million meters): Yeah… Jupiter laughs in ropes. The Greeks would barely get past the planet’s first cloud swirl. That’s like trying to tie down a cruise ship with a shoelace.

Saturn (378 million meters): Another no-go. You’d need 12 times their current rope stash just to outline Saturn’s waistline – and that’s not even counting the rings. Maybe the Greeks could tie a little bow around one of the rings and call it a day?

Uranus (160 million meters): Nope – they’re 130 million meters short. Though honestly, Uranus seems to roll on its side like it’s napping, so maybe it doesn’t need a rope – just a pillow.

Neptune (155 million meters): The Greeks’ ropes wouldn’t even get them halfway. Neptune’s way out there – it’s like trying to use a garden hose to circle the Moon.

The Moon (10 million meters): Now we’re talking! They could wrap the Moon three times over and still have enough rope left to create a “No Parking” zone for incoming

asteroids.

Pluto (7 million meters – if you’re still counting Pluto, which we absolutely are): They could lasso Pluto four times and maybe even give Charon (Pluto’s moon) a little tug to keep it close.

So, while the Greeks can’t tie a ribbon around Jupiter, they’ve definitely got enough rope to hogtie the inner planetsand throw a cosmic boat party on the Moon.